Trucking is a funny industry, for a lot of good reasons, and not-so-good reasons, the trucking industry hangs onto the past. I can go into a lot of examples of this, from my years in the industry. One of my first encounters with trucking, digging in its heels and holding on to the past, was when the steel belted radial tire began to replace the bias ply tires that the industry was familiar with. This subject could be a blog all in itself, so I won't go into detail, other than the fact that it's hard to find a truck today that’s not on radial tires.

Other items that fit this category are drum brakes vs. disc brakes, electronically controlled engines vs. mechanically controlled engines, anti-lock brakes vs. standard brakes, automated manual transmissions vs. manual transmissions... and the list can go on and on from there.

Today, I was thinking about how the fans on automobiles, trucks, and farming equipment were on full-time. There was no clutch. There were no variable speed fans. And there most certainly were not any electric fans which only came on as needed. As we all know, fans with a clutch, variable speed fans, and electric fans have become the industry norm today. The reason for these fans having a clutch, or a variable speed, is because most of the time the cooling system doesn’t need a fan to draw air across its cooling fins. But what would happen if the clutch failed or the electric fan didn’t come on? Surely, this would be a disaster with the engine overheating. Yet, we still embraced this technology, which saves a lot of fuel, and allows more of the engine's developed horsepower to be used to move the vehicle down the road, instead of powering a fan.

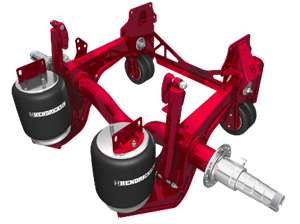

This brings me to my current truck, which we named Celeste, that employs a Hendrickson OPTIMAAX liftable pusher axle configuration. When I bring up the subject with truck salesmen or fleet owners, the biggest reason I hear from them for not adopting this fuel-saving technology, is that it hurts the resale value of the truck too much. When I talk to the drivers about operating a 6x2 liftable pusher-equipped truck, they are quick to point out that it can get stuck easier than a traditional 6x4 configured axle assembly.

Wait a minute!! Did I say traditional combined with a 6x4 axle configuration? Yes! I guess I did! The funny thing about a 6x4 axle configuration, is that the 6x2 tag axle configuration has been around for a longer time in trucking history. Keep in mind that the earliest trucks were all 4x2's, and it wasn't until much later that tag axles were added to increase the weight carrying capacity. Later in time, pusher axles and liftable axles were added to many trucks to increase their freight hauling capabilities. In addition to trucks, all of your large motor coaches, which we share the road with, are also utilizing the 6x4 tag axle configuration. It’s funny how many people look at having a liftable pusher axle as something new when heavy haul, dump trucks, tow trucks, and many other forms of transportation, have been using liftable axles for years, not only on trucks but on their trailers as well.

To the salespeople who speak of the resale value of a truck, like my Freightliner Cascadia, I want to say that this truck will never ever be a farm truck, or a dump truck, in the secondary market. A Cascadia in general will always be a highway tractor for its entire usable life. This means that options that benefit the first owner, will also be of benefit to the secondary market, as well.

To the drivers who speak about the reduced traction; I ask the question, “How many days a year are we actually dealing with a low traction condition caused by snow or ice?”. The reality is, that most days are not going to be an issue, due to traction in snow or ice conditions. In fact, I find this whole subject similar to the pickup truck and SUV market. Everybody, no matter where they live, feel the need as a general rule to have 4x4 or All Wheel drive. The reality is, that most of these 4x4 equipped pickup trucks, SUVs, and station wagons, are only going to be used to go to the mall, grocery store, or other errands. Yet as a nation, we complain that fuel costs are outrageous and at the same time, we buy unnecessary 4-wheel drive configured vehicles that waste fuel.

In my mind, running a 6x4 equipped truck vs. my current Cascadia with its Hendrickson OPTIMAAX liftable pusher axle configuration, is the same as driving a truck with the engine fan on full time. Of course, we would all think that it would be silly and wasteful to leave the engine fan on full-time, and yet we don’t see the waste of driving down the road powering axles that aren’t necessary to carry the load. When I’m light or empty, there’s one axle on the truck, and one axle on the trailer, that is capable of lifting when not needed to carry the load. This means that with this setup, I can go from 5 axles on the ground to as few as 3 axles on the ground.

In addition to lifting axles and tire assembly off the ground, the 6x2 axle configuration also takes out a differential, ring and pinion gear, interaxle differential, a drive shaft, and two u-joints, which all reduce parasitic drag. For anyone who has ever turned a pinion gear by hand, you are keenly aware of how much parasitic drag these components add.

In closing, think of a 6x2 as having less parasitic drag, which means more power to move the load, higher efficiency, and the ability to reduce your costs on toll roads that charge by the axle.