Even though is seems like winter is never going to end, the long, hot days of summer are just around the corner. During the winter, parts of the country have seen temperatures below -40 and those same areas likely will see summer temperatures above +100. That is a temperature swing of 140 degrees and while that doesn’t happen in one day, we do expect our trucks to operate and be profitable through all these temperature changes.

With proper planning and maintenance they will do just that and this is the perfect time to prepare your truck for hot weather. Below are the areas I pay particular attention to in preparing for summer driving in addition to my regular lube, oil and filter changes.

Tire Pressures

Tire Pressures

It has been discussed on this site several times but it’s always worth repeating: running the correct tire pressure is always extremely important but even more so in the summer months with the relentless heat of summer. Everyone knows your tires get hot in the summer but they can easily reach explosive temperatures if they are under inflated or over inflated; we are all familiar with the gators on the freeways. Excessive speed and weight also contribute to high tire temperatures. Assuming no injuries occur during a tire explosion, they almost always cause collateral damage, sometimes very expensive damage.

Batteries

Batteries

These very important items are often overlooked during the summer because cold weather starting problems typically don’t exist. However, as I mentioned in a previous article titled Truck and Automotive Batteries, hot weather is more damaging to your batteries than cold weather and weak batteries can fail during excessive heat. It is important to make sure the batteries are accepting a full charge and the electrolyte levels are full. Clean your battery terminals and wire ends while you are checking your batteries.

Air Conditioner

Check your air conditioner for proper operation and if necessary have the system pressure tested to check for leaks. Fix any items that are leaking such as Schrader valves or cracked hoses and recharge your system as needed. You’ll be happy you did when the thermometer hits the 90s and above.

Windshield Wipers and Window Washer Fluid

Sometimes these items can be overlooked or you may decide to put them off until fall because we are entering good weather driving. Windshield wipers in good condition and plenty of washer fluid are very important in summer for when you pass through the swarm of flying insects in your path. Not enough fluid or wipers that smear will cause decreased visibility which is a safety hazard.

Sometimes these items can be overlooked or you may decide to put them off until fall because we are entering good weather driving. Windshield wipers in good condition and plenty of washer fluid are very important in summer for when you pass through the swarm of flying insects in your path. Not enough fluid or wipers that smear will cause decreased visibility which is a safety hazard.

In certain areas of Oregon we have short-lived, but very large, midge populations. These are tiny gnat-like creatures that congregate and create what looks like large dark clouds. They are completely harmless to humans but devour mosquito larvae; when you pass through one of their clouds, the front of your vehicle, windshield included, will very rapidly turn solid green.

Coolant and Coolant Hoses

Coolant and Coolant Hoses

As discussed in a recent article here on Team Run Smart titled The Relationship Between Lube Oil, Coolants, and Biodiesel by Tom Jackson, and to quote Bill McClusky’s comment “the coolant system is one of the most overlooked systems on a diesel engine,” it is so important to ensure your antifreeze is in good condition and ready to handle the demands of summer driving. In addition to the actual antifreeze, it is important to inspect all coolant hoses. If you bought a used truck like I did then you really don’t know the age or condition of your coolant hoses. A couple years ago I replaced all my coolant hoses which gave me peace of mind and now I know how old the hoses are as time progresses. It was relatively inexpensive and I flushed and replaced the coolant at the same time. It is far cheaper than a breakdown and tow bill, or worse yet, an overheated and blown engine.

Engine Belts

Engine Belts

Inspect all belts and replace any that show signs of wear such as cracks on the inside surface. You might not think about your belts very often, but without them your day is over. I find it interesting to think about how many miles the belts have traveled. In order to calculate this, measure the diameter of the main pulley connected to your crankshaft which drives your belt and pick an average engine RPM.

For this discussion let’s assume your pulley is 8 inches in diameter and you choose 1200 RPM as your average engine speed.

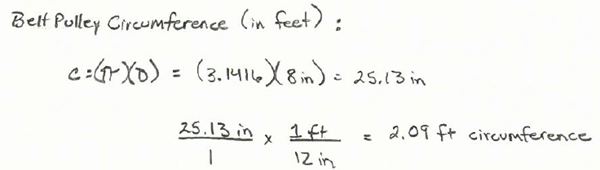

First calculate the pulley circumference in feet.Circumference = (Pi x pulley diameter) / 12 inches per foot.

- Pulley circumference = 3.1416 x 8 in / 12 in/ft = 2.09 feet circumference.

Therefore every time your engine makes one revolution the pulley has traveled 2.09 feet in a circle and assuming a properly tensioned belt with zero slip your belt has also traveled 2.09 feet.

Now with a few simple conversions we can come up with a belt speed in miles per hour. (2.09 ft/revolution) x (1200 revolutions/1 minute) x (60 minutes/1 hour) x (1 mile/5280 ft) = 28.5 miles/hour belt speed.

Keep in mind this is an average based on fictional numbers and I am assuming this speed even when the truck is sitting still in traffic or idling all night. You can estimate the hours your engine has ran or if your truck is equipped with an hour meter you can simply use that number to determine how many miles your belt has traveled.

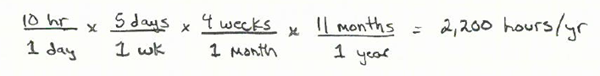

Just for fun let’s assume 10 hours per day, 5 days per week, 4 weeks per month and 11 months per year (everyone needs a little time off). Therefore (10 hours/day) x (5 days/week) x (4 weeks/month) x (11months/year) = 2200 hours per year assuming zero downtime idling.

So if we take (28.5 miles/hour) x (2200 hours / year) we get 62,700 miles per year.

Now just think about how many times that belt flexes back and forth during its cycle. We replace our tires when they become worn at maybe 100,000 miles if we are lucky but people don’t think about replacing belts on a timely basis. Based on the calculations above but using your own numbers and how many years between belt changes, you can get a good idea of how many miles you are getting from your engine belts. And, remember belts are cheap compared to a tow bill.

Do your due diligence with maintenance and hopefully you will have safe and profitable summer travels without any breakdown time. I would like to know what you do to prepare your truck for summer operations so please provide comments and suggestions.