When planning a trip the most effective route is typically the most direct route. There are exceptions to the direct route being the most effective route such as a mountain in the way, dense traffic, weather, and many other scenarios which could divert us from taking the most direct route.

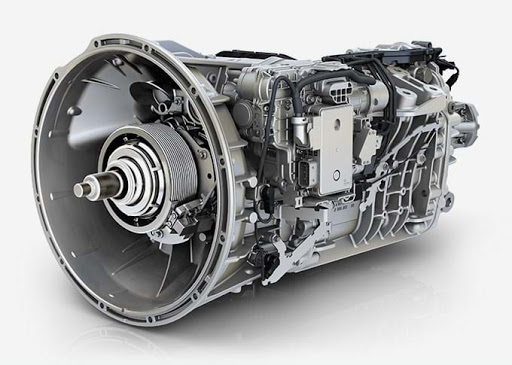

The direct route I would like to discuss in this installment has to do with the driveline of our truck. The inspiration for this installment came from a conversation with one of my friends in the trucking industry. I was discussing overall gear ratio when my friend stopped me and asked me to explain what I was talking about. Overall gear ratio would be the relationship between an engine’s RPMs and the revolutions of your tire per mile traveled. There has been a lot of talk over the last decade over the efficiency gains that are to be realized using a direct drive transmission.

This is where much of the confusion comes in because most people associate the rear axle ratio as the prime number relating to a vehicle's ability to perform in regards to acceleration or ability to maintain speed on a grade. On a typical transmission from the past, an overdrive ratio in the neighborhood of .73 was generally employed along with a rear axle ratio somewhere between 3.73 to 1 up to a 3.23 to 1.

So, what does this all mean in regards to overall gear ratio? Let's start with the transmission with an overdrive ratio of .73. .73 was a typical overdrive ratio for the owner-operator preferred 13-speed transmission. .73 is the number that describes the difference between the input and output shaft speeds of the input and output speeds of the transmission. This would mean the input shaft is turning .73 of a turn for 1 turn of the output shaft. Another way to look at this with a .73 overdrive ratio would be that the output shaft of the transmission is turning 1.27 turns for every turn of the input shaft. A typical rear axle ratio that would accompany these transmissions was a 3.42 to 1 rear axle ratio. To figure the overall gear ratio for any given vehicle would be to multiply the overdrive ratio by the rear axle ratio which would give you the overall gear ratio. In this case, with a .73 overdrive ratio and a 3.42 rear axle ratio, the equation would equal 2.496 to 1 as an overall ratio. In the case described above, this would mean the engine is turning 2.496 turns for each revolution of the wheel. When I first began to use a direct drive transmission for fuel economy-related objectives, I employed a 2.50 to 1 rear axle ratio to mimic the overall gear ratio I was accustomed to in my previous truck equipped with a 3.42 to 1 rear axle ratio with a .73 transmission overdrive ratio. This was over a decade ago and today I am employing a 2.16 to 1 rear axle ratio.

The funny thing was that everyone would tell me there was no way that a truck could pull a grade with a 2.50 to 1 rear axle ratio with a direct drive transmission, yet they had no qualms of a truck pulling a grade with a .73 overdrive ratio transmission transferring power to a 3.42 to 1 rear axle ratio.

The advantage to a direct drive transmission is that the transmission is not transmitting power through extra gears which all contribute to a parasitic loss of power and fuel efficiency as the engine's power is transmitted to the rear axle gear set. Today's Detroit DT12 is offered in a direct drive or an overdrive with a ratio of .78 typical direct drive. Rear-axle ratios will range from 2.41 to 2.16 to 1 and the overdrive ratios employed in the rear axle are generally between 3.07 and 2.64 to 1.

Let's take a common direct drive ratio of 2.28 to 1 and compare it to what would be required to have the same overall gear ratio with an overdrive transmission. In this case, the overdrive ratio would be .78 which we will take and multiply by a rear axle ratio of 2.85 to 1 which would equal 2.223. This is only 4/100ths of a revolution different than the 2.28 rear axle ratio employed in the more efficient direct drive transmission.

It is my hope that this installment will help dispel many of the misunderstandings that have resulted as the trend towards fuel-efficient direct drive transmissions continues. However, there is still a case for an overdrive transmission where there is not a gear ratio available to obtain the goals dictated by certain operations. An example would be a duty cycle where a truck spends a large portion of its time below top gear in a local short-haul scenario, but we can go over that another time.